Please refer to the table below for current product specifications.

| Name | Model | Specification(mm) | ||||

| Diameter | Vertical height | Total height | Cover | Interface | ||

| Cylindrical water tank |

PT-250L | 653 | 740 | 950 | 400 | 20 |

| PT-400L | 740 | 890 | 1150 | 400 | 20 | |

| PT-500L | 796 | 1000 | 1250 | 400 | 25 | |

| PT-1000L | 1073 | 1065 | 1410 | 400 | 25 | |

| PT-1500L | 1320 | 1100 | 1430 | 400 | 40 | |

| PT-2000L | 1320 | 1410 | 1785 | 400 | 40 | |

| PT-3000L | 1584 | 1635 | 2020 | 400 | 50 | |

| PT-5000L | 1880 | 1740 | 2115 | 600 | 50 | |

| PT-6000L | 1880 | 2060 | 2440 | 600 | 50 | |

| PT-8000L | 2315 | 2040 | 2520 | 600 | 50 | |

| PT-10000L | 2315 | 2470 | 3050 | 600 | 50 | |

| PT-15000L | 2700 | 2820 | 3350 | 600 | 50 | |

| PT-20000L | 2700 | 3790 | 4300 | 600 | 50 | |

| PT-30000L | 3200 | 3600 | 4350 | 600 | 80 | |

| PT-40000L | 3200 | 4850 | 5600 | 600 | 80 | |

| PT-50000L | 3200 | 6100 | 6850 | 600 | 80 | |

1, The PT series cylindrical water tank is formed by one-time molding of Samsung raw materials imported from South Korea. Its performance is acid resistance, alkali resistance and high temperature resistance (-20°C ~ 60°C).

2, PT series products are divided into three levels: A, B, and special. Class A is for indoor water placement.

3, PT series cylindrical water tank specifications from 250L ~ 30000L, a total of more than 20 kinds of products.

4, commonly used colors are orange, blue, green, black optional.

It is smooth inside and outside, has good hygienic and anti-ultraviolet ability, impact resistance, strong shock resistance, not easy to aging, not long algae, easy to clean, anti-mouse and termite prevention, easy to install and move.

Secondary water supply for high-rise buildings, water storage in towns and rural areas, widely used in food, pharmaceutical, hotel, hotel, electronics, chemical and other industries.

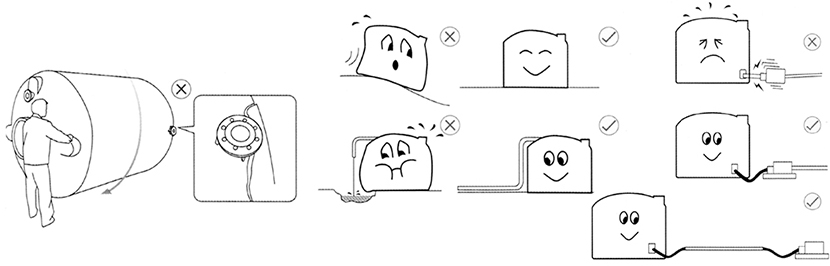

1. The cement floor foundation on which the storage tank is installed must be horizontal and can withstand the corresponding bearing capacity. For example, it should be used in the air steel structure, the gap should not be too large, and the iron plate should be laid on top to keep the level and ensure the bottom surface of the tank is flat. To increase the life of the tank.

Second, before storage of chemical storage tanks, it is best to use water to test leaks to prevent unnecessary losses. There should be a good drainage ditch and dilution device around the site. Please call us when changing the liquid.

3. Since the tank is inevitably formed into a spherical crown when it is formed in the tank, the foundation must be flat. It is recommended to use the yellow sand to form a spherical crown corresponding to the bottom of the tank on the basis of the level.

4. Openings and fittings are configured according to the application provided by the customer. There are PE flanges and PE interfaces; PVC, ABS, stainless steel and iron interfaces are available. Strong acid, strong alkali, organic solvent feed port and discharge port are connected by PE material flange. If you need to contain 98% concentrated sulfuric acid, 65% concentrated nitric acid, organic solvent (acetone, formaldehyde, toluene, etc.), directly with our company. Contact, our company provides special formula.

5. The pipe connected to the lower joint or flange of the tank should be perpendicular to the wall of the tank. It is best to use a soft connection or a shock absorber. If the tank is more than 10 cubic meters, please arrange a reinforcing sleeve to avoid filling the wall with the liquid. Uneven expansion causes the connection of the discharge port to be damaged, resulting in leakage. In severe cases, damage the joint and the whole body, unloading and installing, please use the crane or inquire about the operation.

6. When installing a heavier auxiliary equipment such as a mixer on the barrel, or if the person has to work on the top of the tank and the top of the tank cannot bear the weight of the person, please make another shelf or ladder and pay attention to the safety of the work. If the liquid cannot be controlled, an overflow port should be installed to prevent the liquid from overflowing from the manhole and causing unnecessary damage.

7. If you are not sure whether a certain substance can be contained, please consult the company or refer to the online “Chemical Performance Table”.

8. All the storage outlets, interfaces, flanges and flange ball valves of the company must be inspected once a quarter. The problems are dealt with in a timely manner, usually replaced in 1-2 years.

Contact:Hu XuDong

Mobile:+86 18958342288

Tel:+86 574-63296168

+86 13567408555

Tel:+86 574-63295000

+86 15381396555

Email:643477207@qq.com

Address:HangZhou Bay Developing Zone, Cixi, Zhejiang, China